News

LIFEVIEW PDAII providing real and effective partial discharge monitoring

27 April 2022

Thanks to the LIFEVIEW® PDA II condition monitoring system, our client - a major industrial plant in Europe, was able to effectively monitor the insulation condition of an 11.3kV generator in two very different ways.

- Monitoring the degrading insulation to help identify when machine failure was imminent & plan for repair

- Following repair - monitoring machine running at maximum load without fear of failure

Read on to discover how the LIFEVIEW® PDA II system allowed the client to return a failing machine into service whilst planning for a necessary repair before catastrophic machine failure occurred, whilst limiting loss of operational hours …

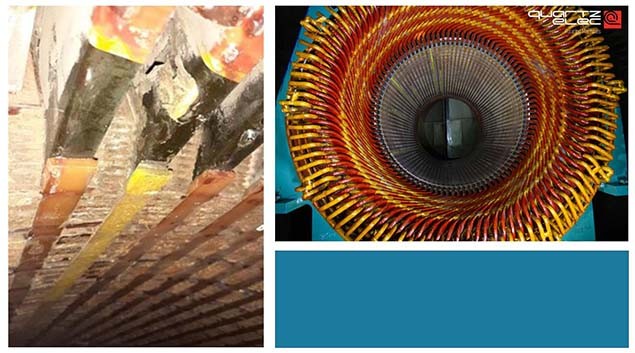

This critical machine had previously experienced a rotor failure and Quartzelec were asked to carry out inspections of the rotor and stator to identify what the key issues were and how quickly the machine could be placed back in service.

It was clear that the stator winding was also experiencing a degradation of the insulation system having been subject to some partial discharge (PD), through stator bar vibration sparking and that in addition to the rotor repairs, a repair to the stator winding was also recommended.

Due to the criticality of this machine, the client was requesting a solution which would allow the machine to be returned to service as quickly as possible.

Our Engineers proposed that the machine was fitted with our Quartzteq LIFEVIEW PDA II monitoring system. With the reliable trending data afforded by the solution, the owner/operator was able to constantly monitor the machine condition whilst still having the ability to generate at a load that would not lead to any operational issues or even critical failure.

This early detection and trending of PD enabled the customer to manage the generator load and nurse it to a pre-planned shutdown which significantly reduced the cost of repair and downtime of the machine and prevented consequential damages and safety issues.

Once the final repairs were complete and the machine re-installed into service, the PDAII was then focussed on monitoring the now significantly decreased levels of PD with the Operator now comfortable with running the machine at its maximum load without fear of failure.

The LIFEVIEW PDA II is a permanent online condition monitoring system suitable for high voltage rotating machines, providing a continuous monitoring of partial discharge activity and insulation conditions of the machine. Available for installation in safe and hazardous areas, the LIFEVIEW PDA II is an ideal solution for an effective, low cost, user-friendly monitoring system without complex software.

LIFEVIEW condition monitoring systems provide online knowledge on the insulation of machines and help in identifying early warnings of critical problems so that a decision can be made on whether intervention is required, preventing unnecessary downtime and protecting against costly damage.

For more information about the LIFEVIEW Condition Monitoring range of products, click on the link: http://bit.ly/3cxRcvC